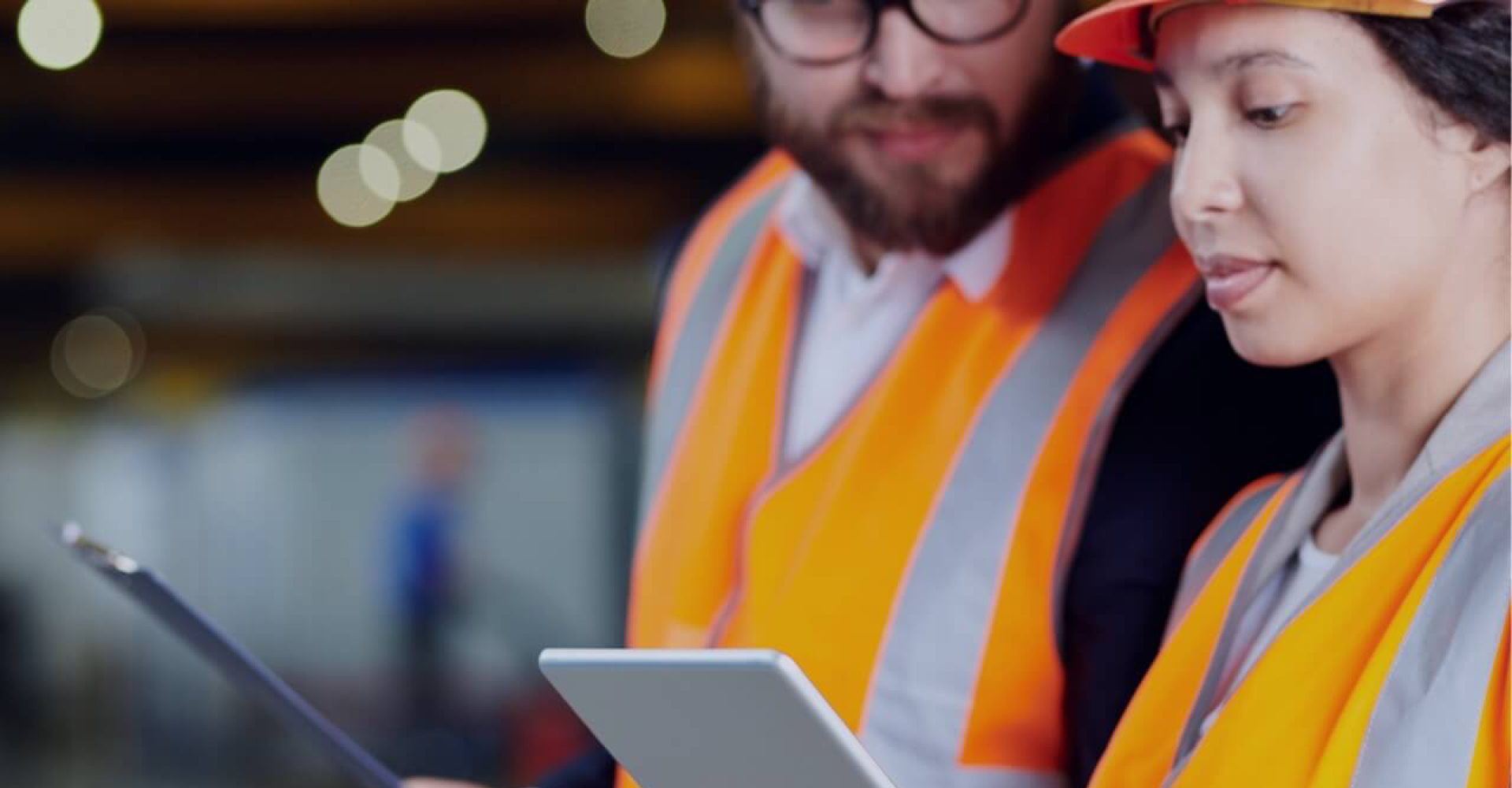

Securing Operational Technology

Industry 4.0 brings the convergence of IT and OT and exposes new security risks to prevent and defend against

IT - OT Convergence

Moving towards digitization and automation

For many years, industrial systems were standalone, monitored by people, and with little or no connection to a network, and as such, posed an insignificant target for attackers. OT and IT integrated rarely.

Today, industrial systems are moving towards digitization and automation to deliver new capabilities and efficiencies through technological integrations and innovative technologies. IT and OT convergence is growing rapidly to improve operational performance, resulting in creating a complex landscape with the need to manage cyberthreats, vulnerabilities and risk.

The Growing Cyberthreat

Enhancing and Securing Operational Resilience

Is your Supply chain or ICS environment vulnerable?

CylancePROTECT does more than stop breaches—it prevents them from happening.

Prepare

Prevent

Respond

All industries are distinct in their operational focus, many with extensive physical infrastructures, that requires the development of a bespoke systematic approach to assessing and maintaining the security posture of their ICS systems, including legacy architectures, legacy systems, and legacy devices, without replacement.

Hans-Peter Bauer, Senior Vice President - EMEA Sales, Cybersecurity

More material and Insights